About us

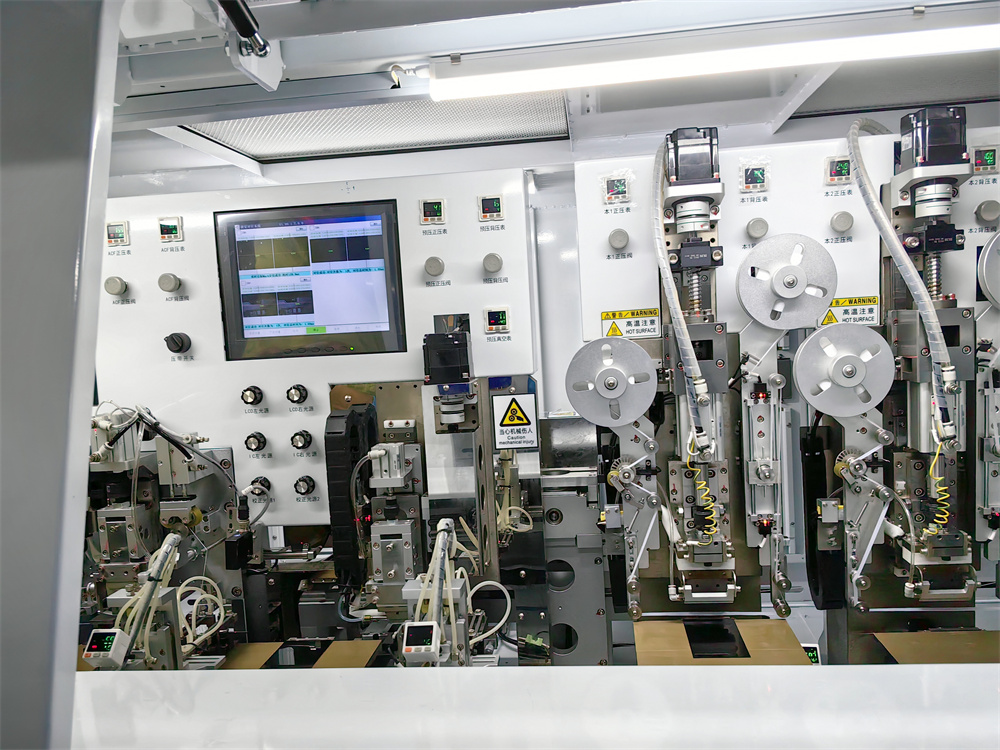

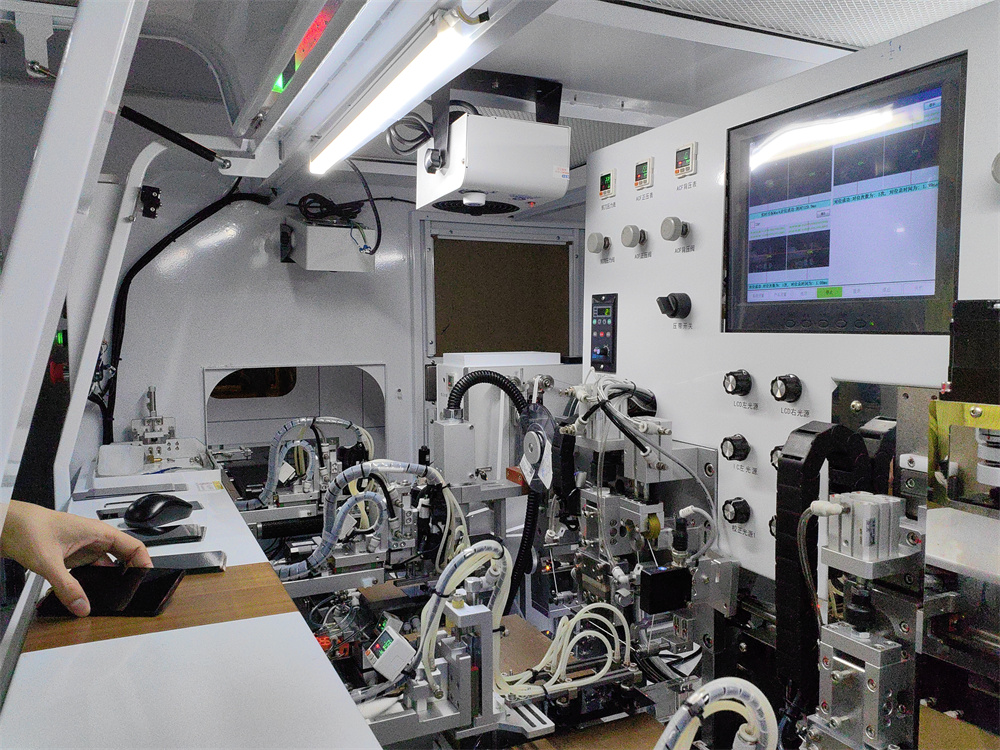

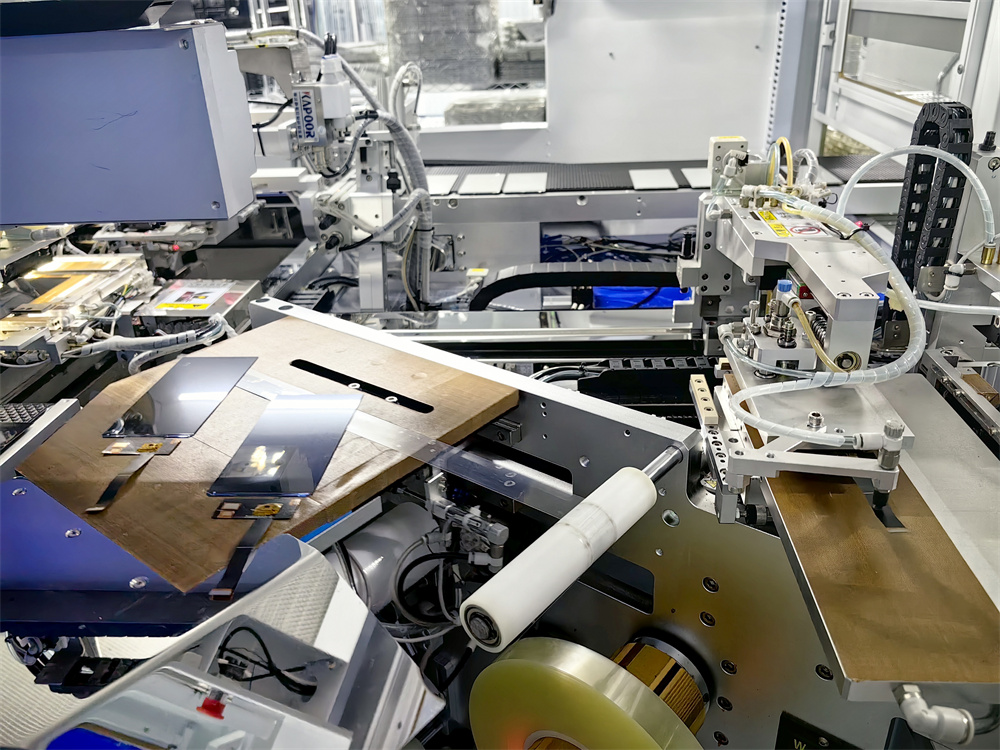

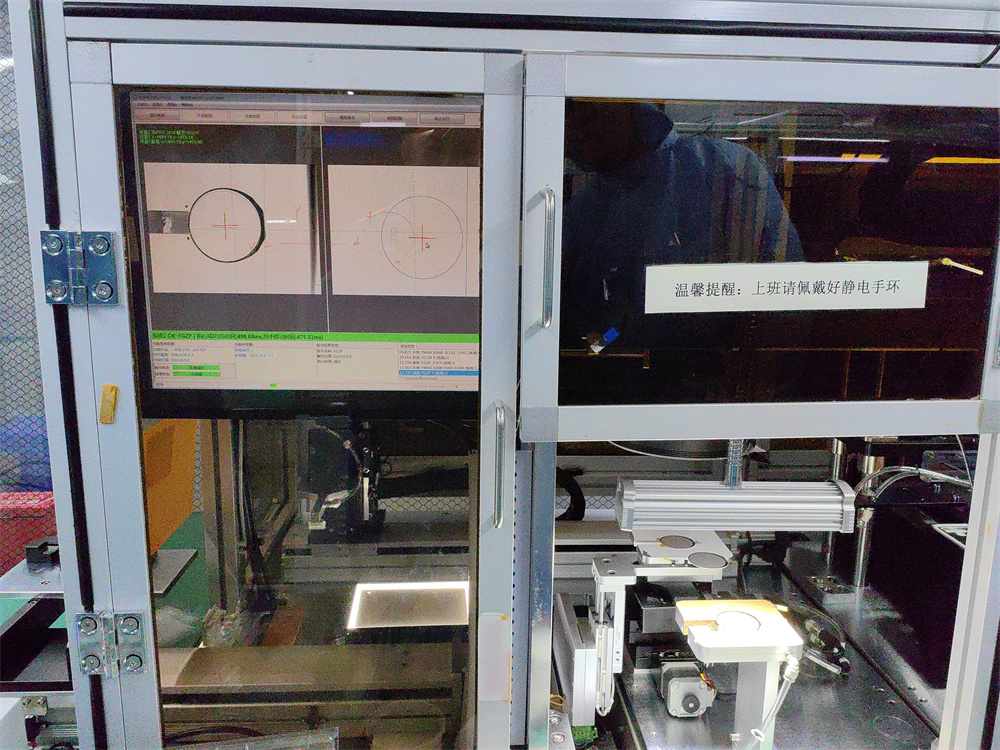

Shenzhen Ruihanfeng Technology Co., Ltd. it was founded in 2012, is a professional R & D, design and production of small and medium-sized large size TFT OLED LCD and touch screen high-tech enterprises, the company has a rich and professional R & D team personnel and practical cases to open mold and custom products according to customer requirements. The factory is located in Baoan District, Shenzhen, with a total area of nearly 3000 square meters, strong technical force and complete equipment. Our products are widely used in: smart home, wearable devices, industrial, medical, consumer electronics, handheld devices, POS, automotive industry and etc. The company has advanced equipment imported from Japan Panasonic, high-precision prepress, this press, hot press, ACF attaching machine, terminal cleaning machine, OCF laminator group, differential interference microscope, electrostatic test gun and high and low temperature experiment box, dust workshop, and has a number of semi-automatic, automatic production lines, To provide customers with a stable and efficient supply of 0.96 inch ~ 32 inch LCD module, and is through the ISO9001 and ISO14001 certified manufacturers and TS16949 qualified producers

The company will always adhere to the innovation and development strategy, strengthen the LCD industry, take into account the vertical integration of upstream and downstream development, with the pragmatic wind, the spirit of hard work, committed to becoming a global small and medium-sized enterprises LCD screen quality supplier. Through years of development, has developed into a research and development, production, sales and service in one of the innovative development of enterprises, products are sold at home and abroad, and customers unanimously recognized and praised.

Of happy users

The company has advanced imported CNC equipment, such as HAAS Machining Center of the United States (including five axis linkage), Japanese CITIZEN/TSUGAMI (six axis) precision turning and milling compound machine, HEXAGON automatic CMM, etc. Ensure the quality reliability of each product in each production stage. At the same time also implemented factory digitization, such as ERP/MES system, to further improve the guarantee from sample manufacturing to mass production.

Looking forward to the future, the company will continue to uphold the business philosophy of "quality first, customer oriented, perfect service, reasonable prices", keeping up with the pace of the times, proceed to develop and produce products in line with customer needs. At the same time, we will integrate comprehensive advantages of company resources, and establish friendly and cooperative relations with customers from around the world. We will develop and implement clear standards, continue to upgrade, and gradually improve the competitiveness of the company, so as to achieve win-win situation. We are dedicated to provide you with product consultation, design service, solutions and perfect after-sales service.

Certificate

Quality Control

History

2021Main module/touch assembly manufacturing and R&D

2021Build a large size fit line

2019Fully automated production equipment upgrading and Complete industrial computer solution

2016Set up capacitive screen business department

2014Cut & etch LCD panel to smaller and thinner